Tomato on the vine handling system

The tomato handling line for tomatoes on the vine can consist of next modules:

Box/crate pusher

The harvesting cart drives into the pusher unit. The boxes/crates are then pushed off the rollertrack onto the portal table.

A scissor pusher can be used to push empty boxes/crates onto the harvesting cart.

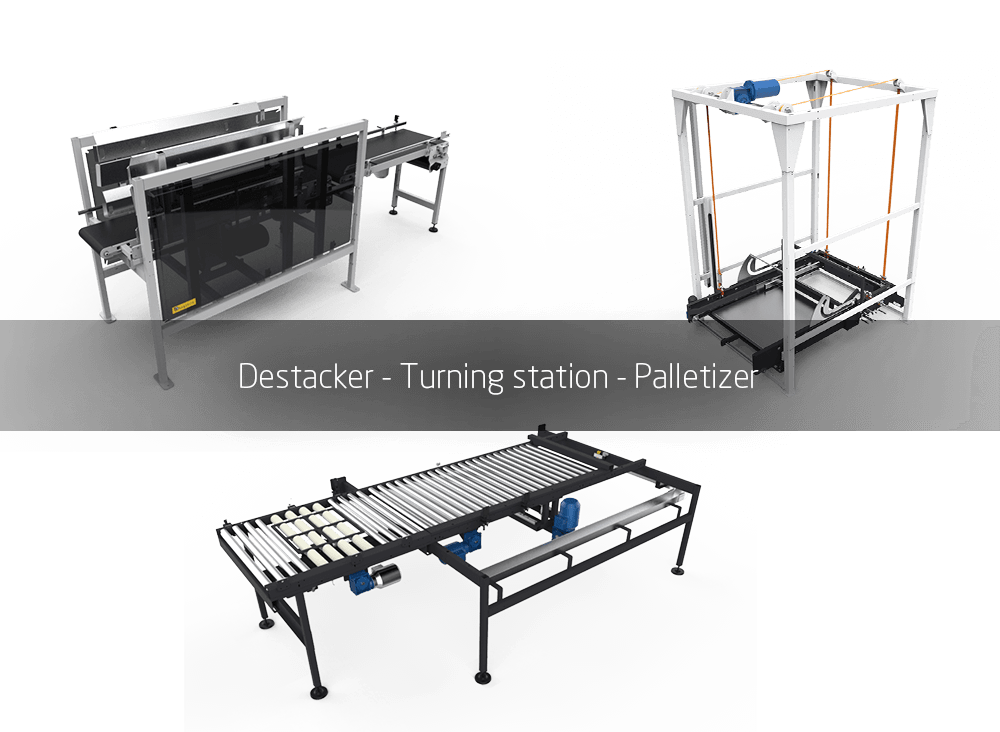

From destacking unit to weighing stations

A gripper picks up the boxes/crates and places them on a conveyor belt. This conveyor belt distributes the boxes over the weighing stations where employees weigh and pack the tomatoes.

From pre-stacker with turn station to palletizer

After the weighing table, people can put the full boxes on the collection belt conveyor, from where they can go to a pre-stacker with turn station followed by a palletizer. These modules stack boxes/crates in layers and move the layer formation to the pallet.

Modular belt conveyors, roller conveyors

Different lengths/widths possible.

A handling system is modular, always custom made: depending on the needs/desires of the customer and the available space in the packing hall. Together with the customer, Bogaerts greenhouse logistics always finds the best solution.

© BogaertsGL.com | Privacy policy