Beef tomato handling system

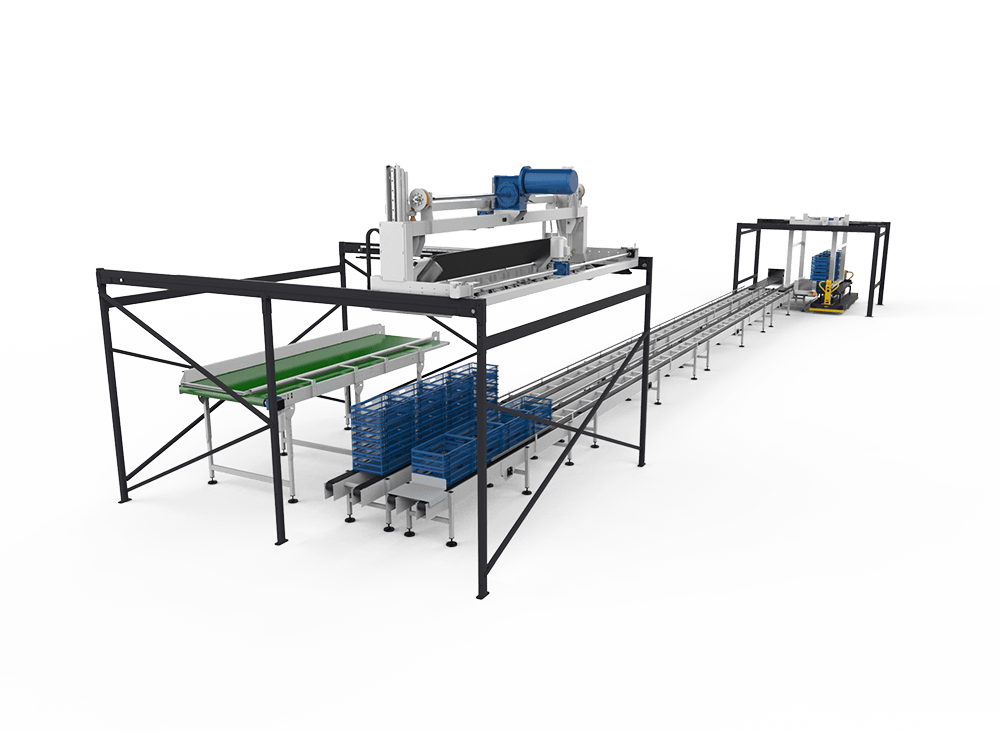

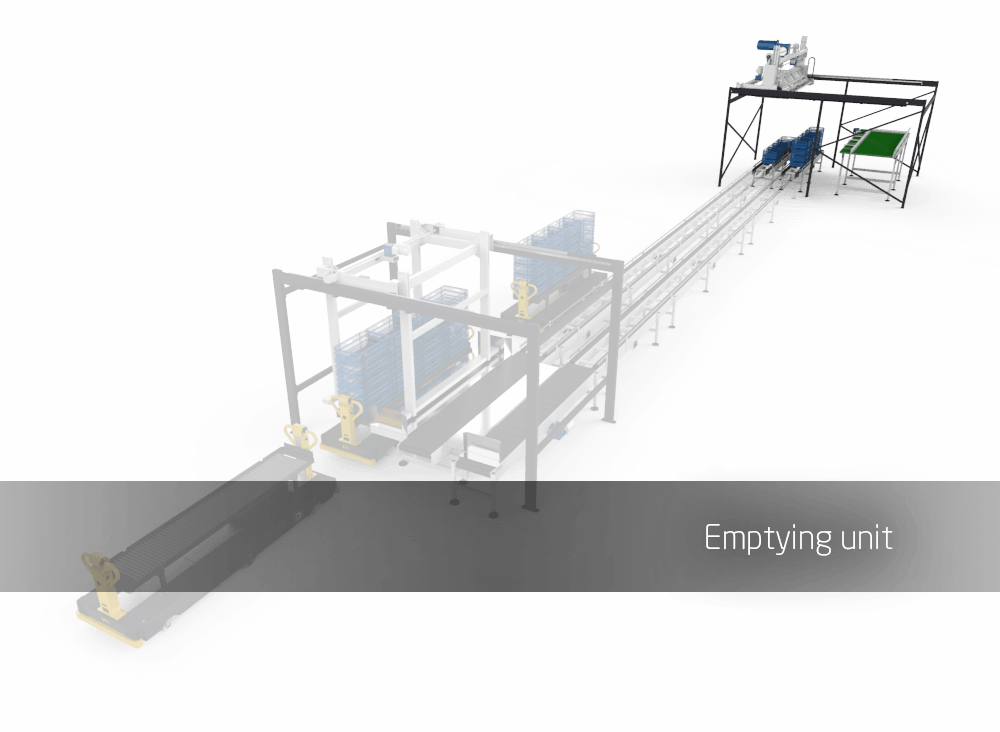

The tomato handling line for beef tomatoes can consist of next modules:

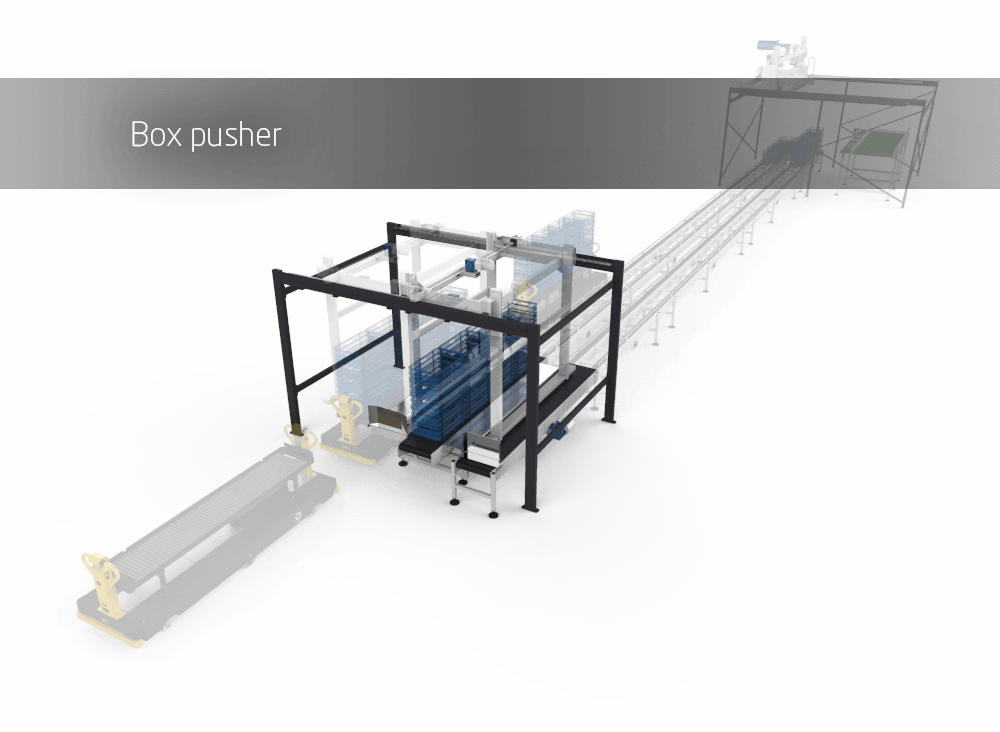

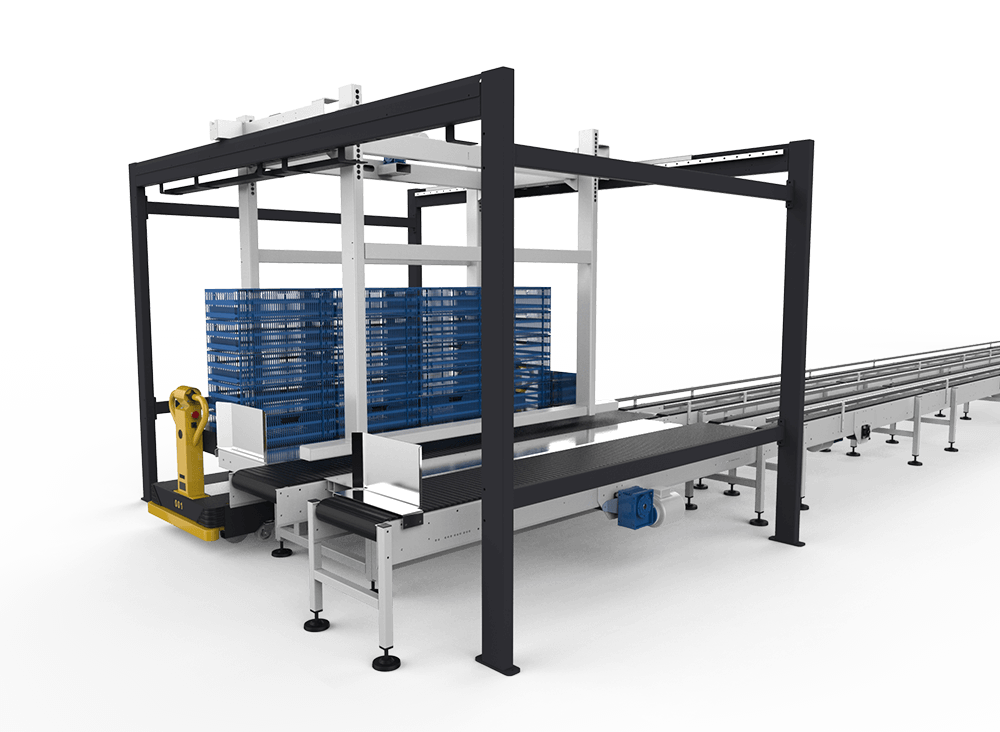

Portal Pusher

The harvesting cart drives into the pusher unit. When the cart is in position, the pusher starts automatically unloading the cart, when this cycle is done, it pushes empty crates/boxes on that same cart.

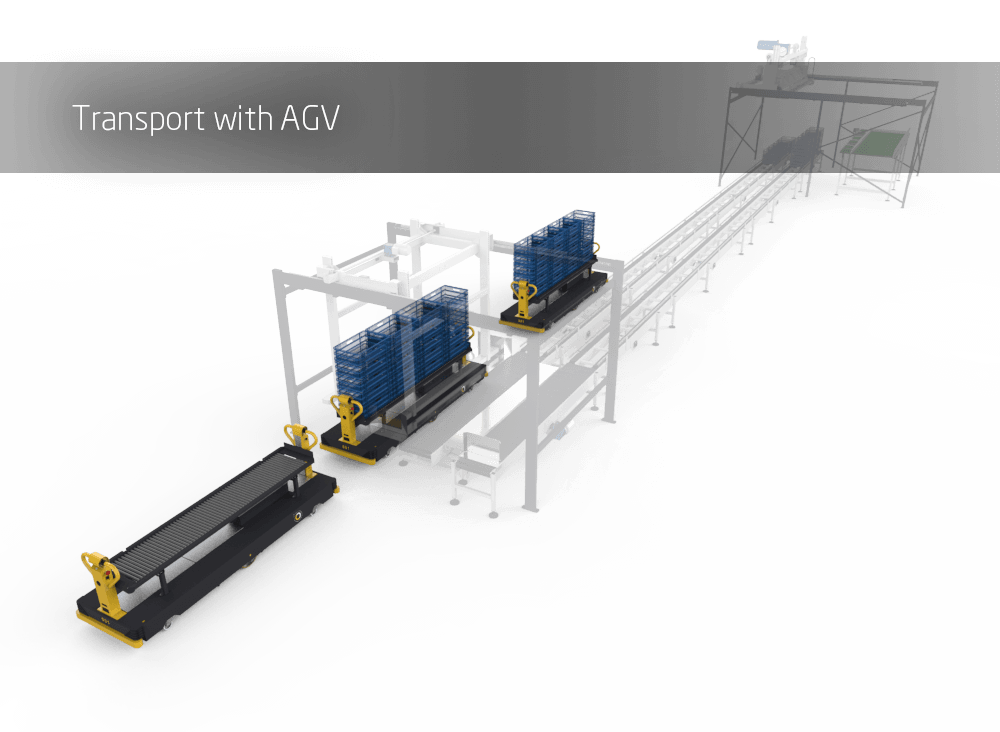

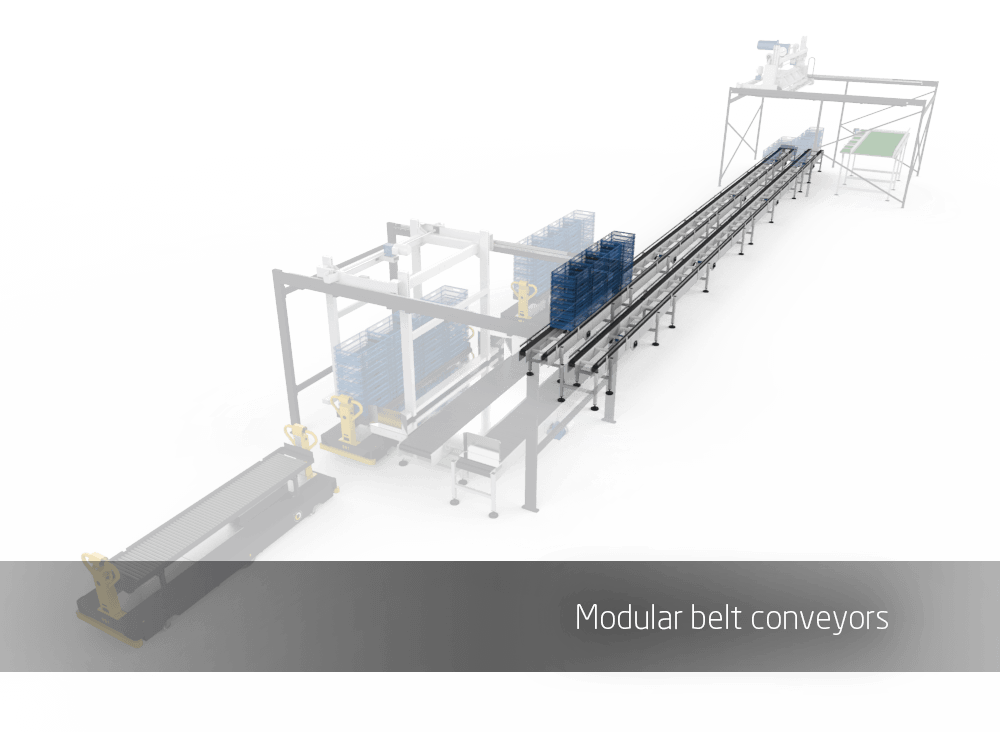

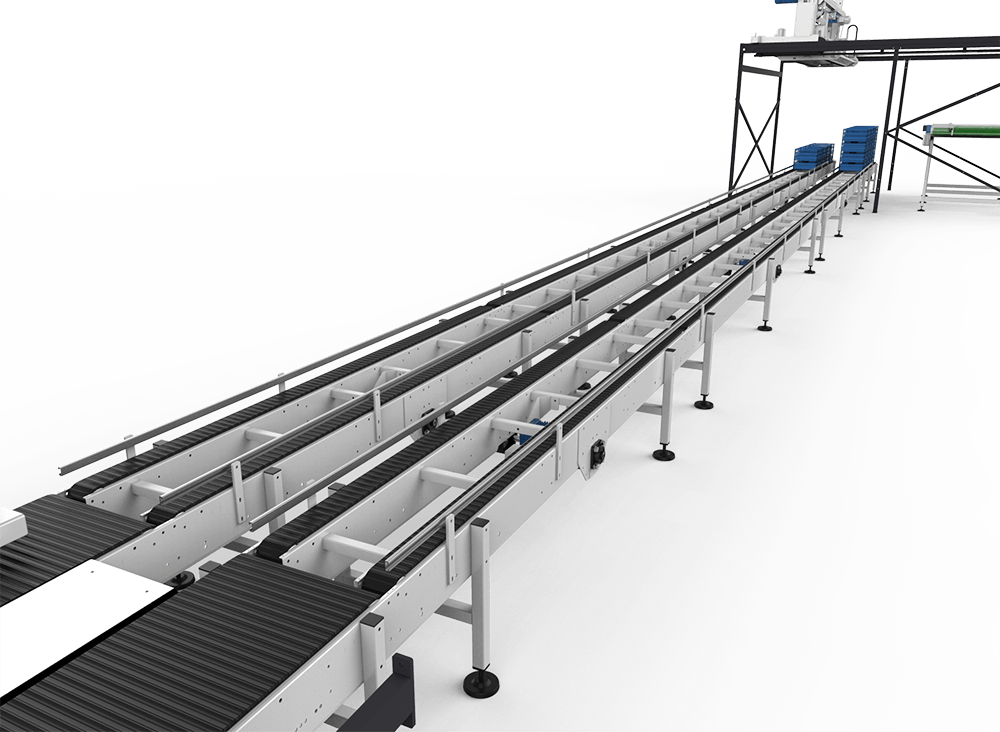

Modular belt conveyors, roller conveyors

Different lengths/widths possible.

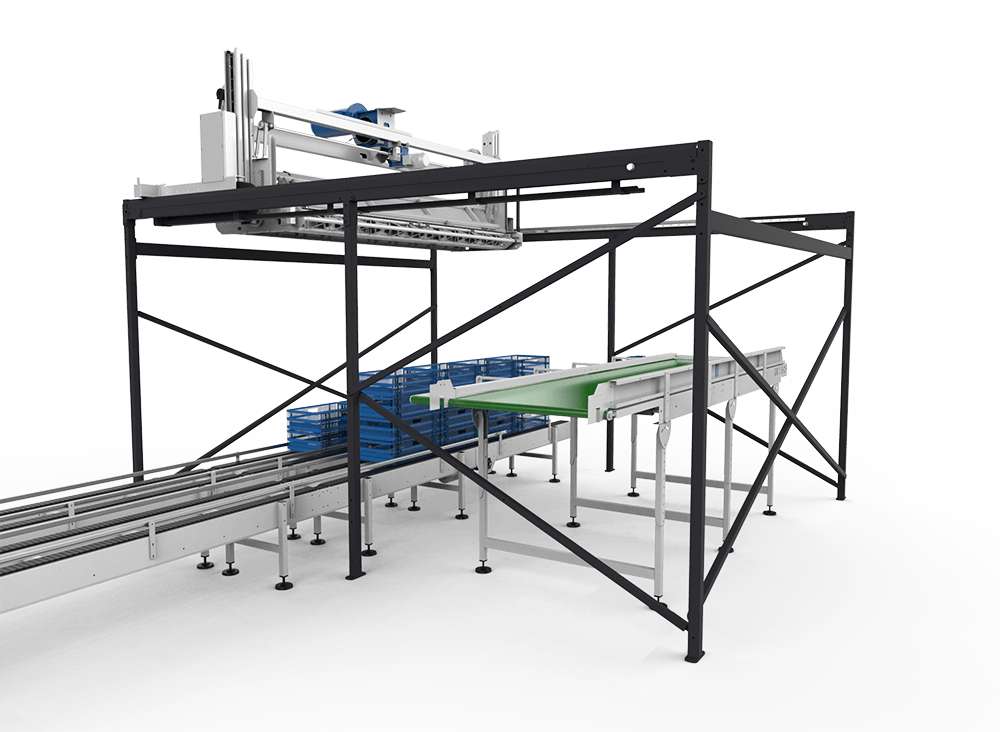

Emptying unit

The boxes are now transported to the emptying unit. The robot picks up a row of boxes and flips them over onto a conveyor belt very carefully so the tomatoes do not get bruised. The conveyor belt transports the tomatoes to a sorting machine.

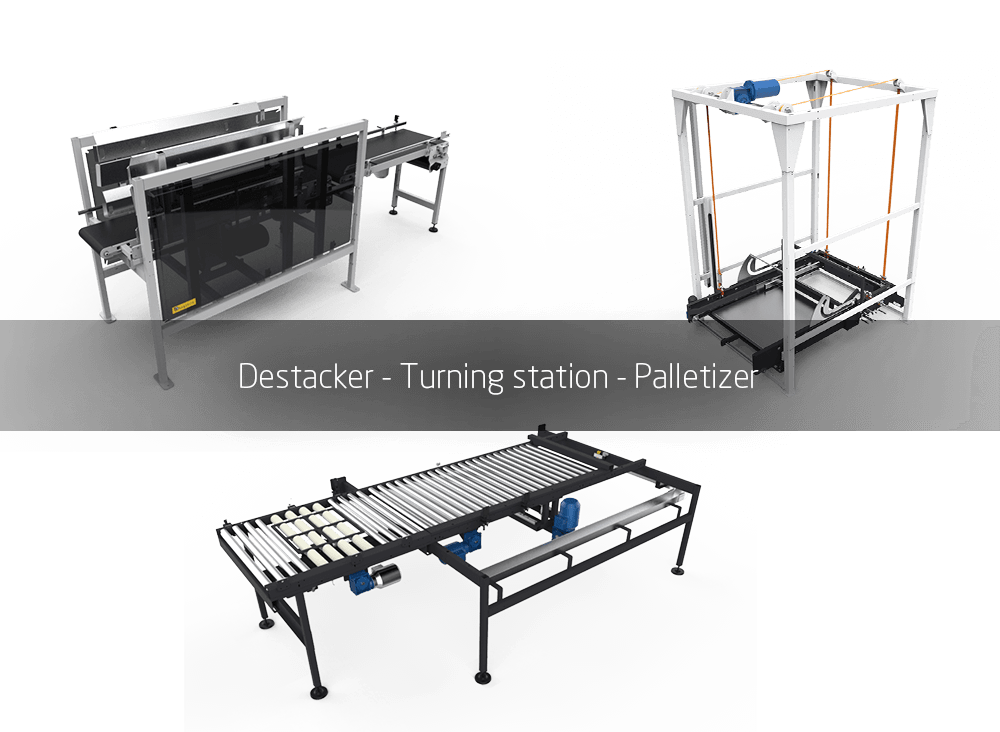

From pre-stacker with turn station to palletizer

A pre-stacker with turn station followed by a palletizer can be used to stack full boxes/crates in layers and move the layer formation to the pallet.

A handling system is modular, always custom made: depending on the needs/desires of the customer and the available space in the packing hall. Together with the customer, Bogaerts greenhouse logistics always finds the best solution.

© BogaertsGL.com | Privacy policy