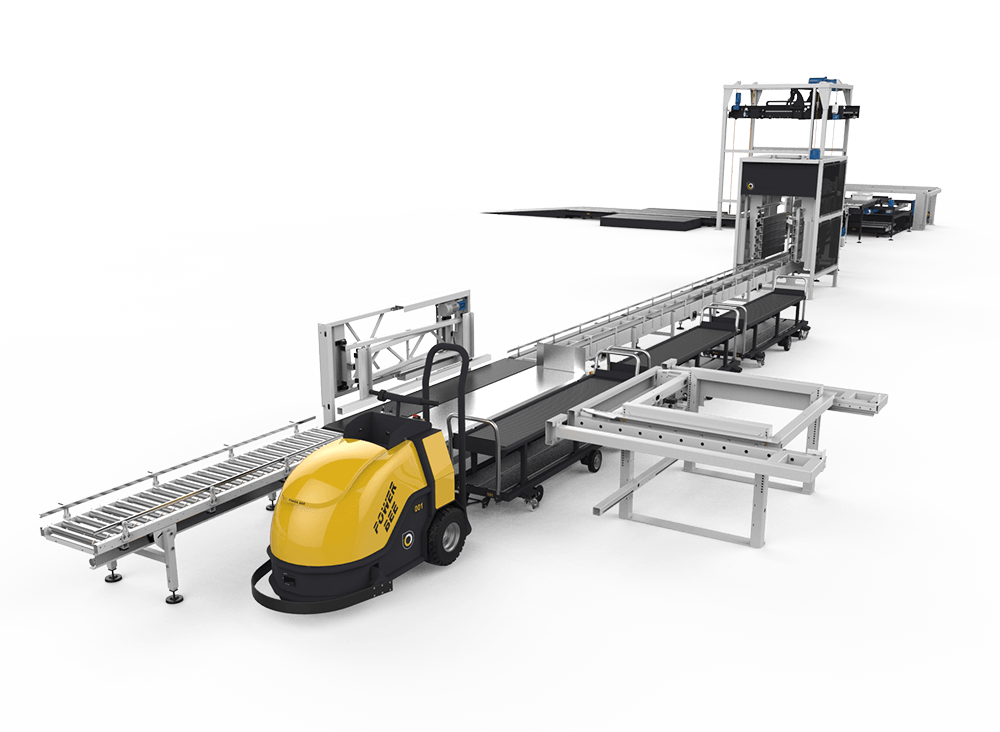

Eggplant handling system

The eggplant handling system is a system that is used to automate the packaging and transporting of eggplants.

There are different degrees of automation: The automation can start in the greenhouse, or it can start in the packing hall.

- Fully automated: The eggplant handling system operates in combination with the Qii-Drive or the Power Bee AGV which pulls the Bo Cart harvesting carts. They drive automatically to and from the eggplant handling system, guided by an induction course.

- Semi-automated: You can also use an eggplant handling unit in combination with a hand-operated Power Bee which pulls Bo Cart harvesting carts with rollertrack.

A handling system is modular, always custom made: depending on the needs/desires of the customer and the available space in the packing hall. Together with the customer, Bogaerts greenhouse logistics always finds the best solution.

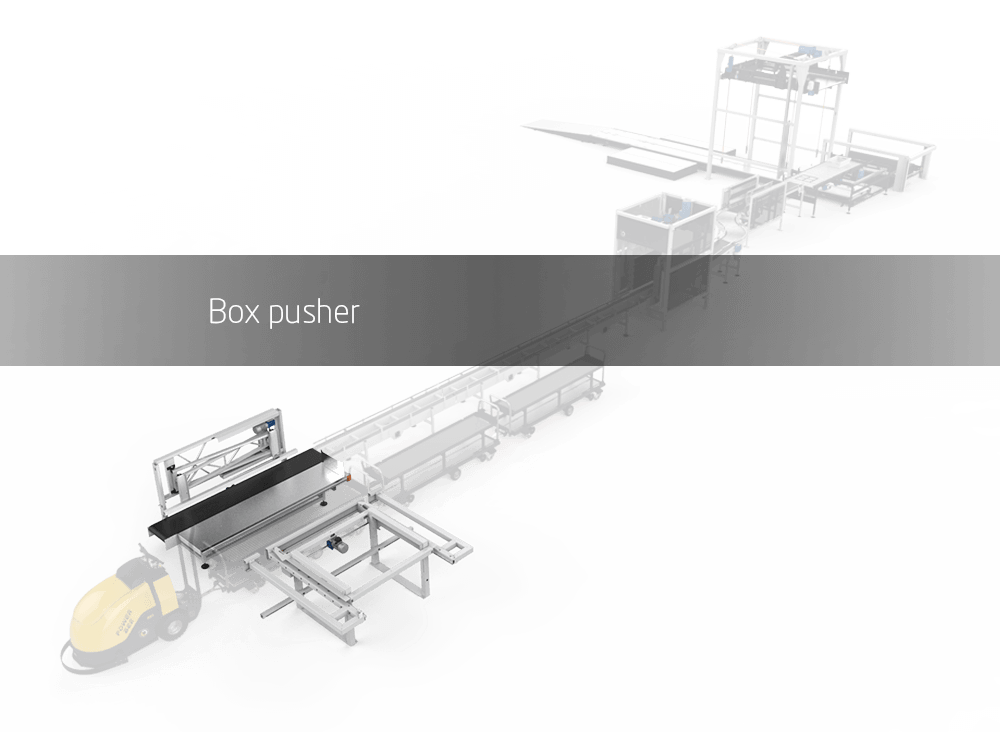

Box/crate pusher

The Power Bee drives the Bo Carts into the pusher unit. The boxes are then pushed off the Bo Cart onto a conveyor belt.

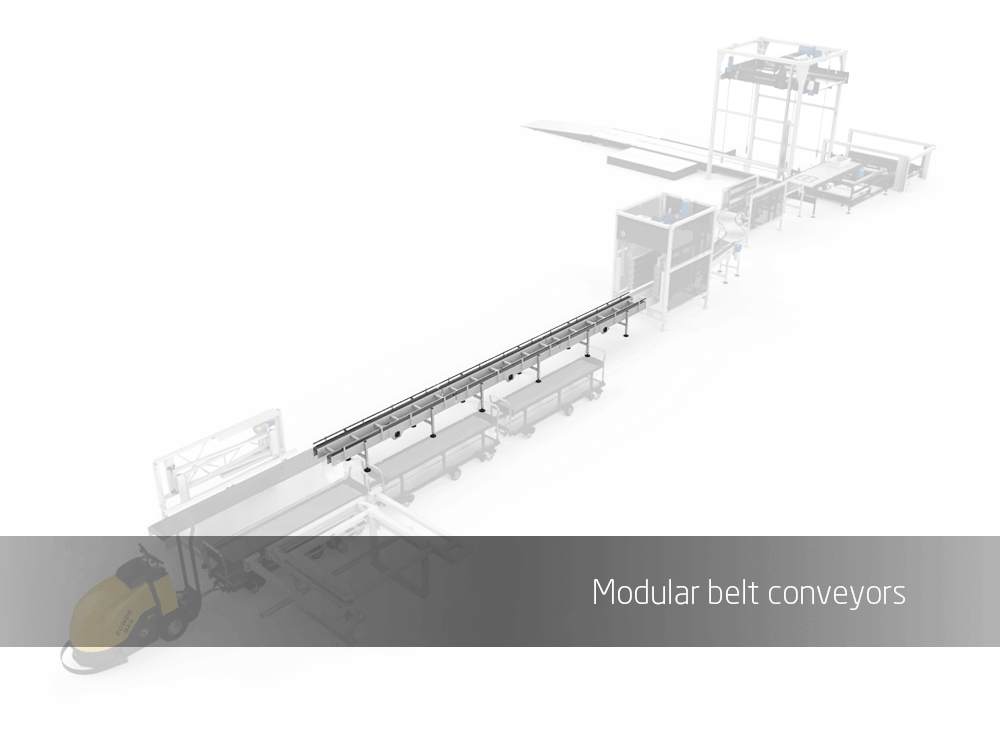

Modular belt conveyors

With different lengths

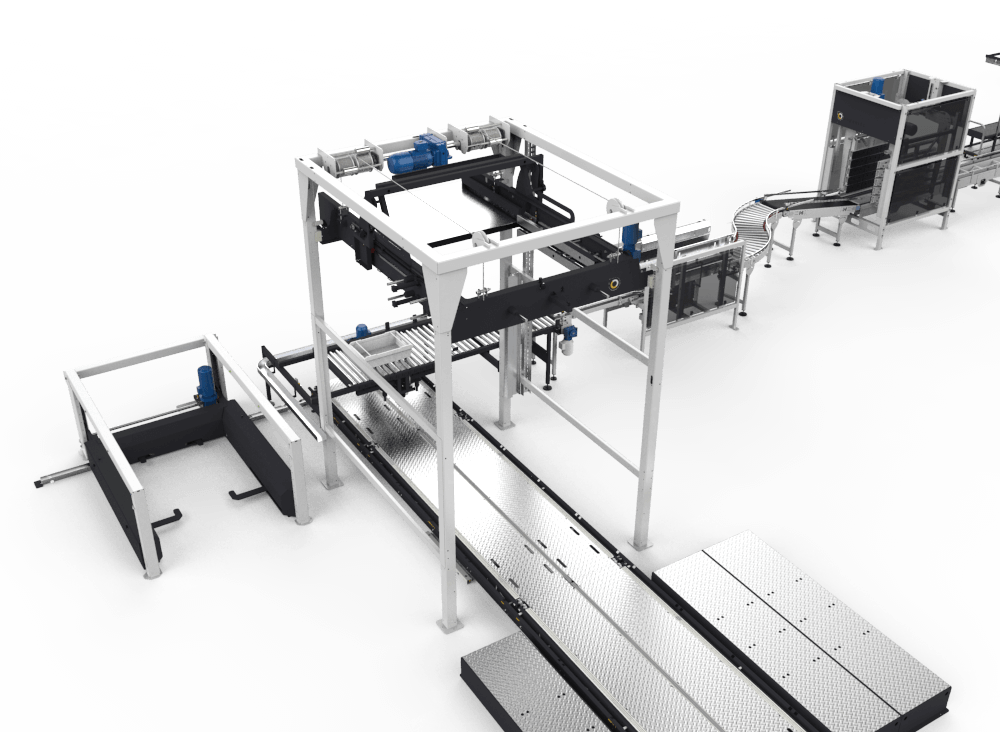

Destacking unit

The conveyor belt transports the boxes through the destacking unit, which unstacks the boxes from 6-7 boxes high to 1 box high.

Palletizer

The layer formation box palletizer moves layers of boxes or crates from the layer formation table to the pallet on a steel plate.

© BogaertsGL.com | Privacy policy